2770

2770

2017-02-05

2017-02-05

Apple has invented a method for carrying out a “laser polishing” technique which could be used to help create future ceramic iPhones.

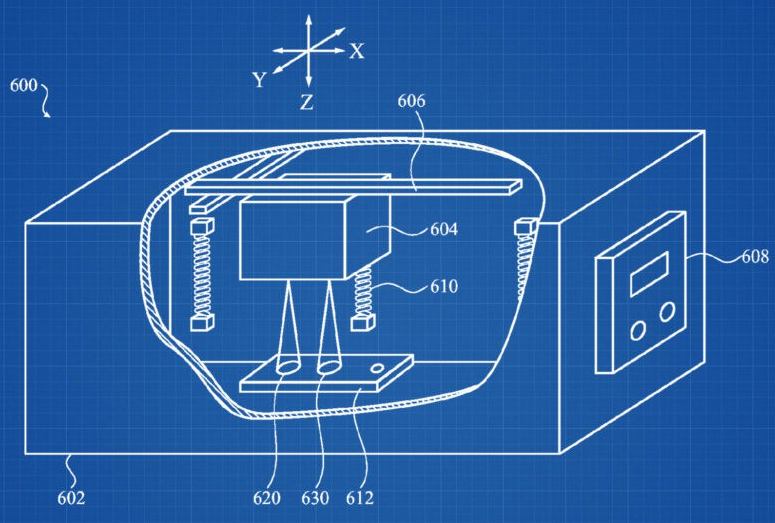

The company’s patent application covers an industrial process designed “for polishing a ceramic component using a laser.” The technique could be used to “produce a polished surface” on a wide range of materials, ranging from the white ceramic used for high-end Apple Watch Series 2 models to glass materials, like the reported casing being used for this year’s iPhone 8.

There are multiple reasons Apple may choose to embrace these materials. In the case of the glass enclosure for the iPhone 8, it is reported that it may be related to Apple’s wireless charging technology, which is expected to be a big selling point of this year’s iPhone refresh.

With ceramic materials like the high-end ceramic Apple Watch Edition replacement it offers almost unparalleled hardness, making devices impervious to scuffs and scratches. As my colleague Killian Bell noted in an article on why a ceramic iPhone would be good, zirconia ceramic — which is what Apple uses for the new Watch Edition — is rated 8.5 on the Mohs scale of mineral hardness. In comparison, steel is rated 4.5, while aluminum is rated just 2.5 to 3.

As with any patent, of course, there’s no guarantee any of this actually comes to pass. Still, it’s exciting to see that Apple is — as ever — remaining on the cutting edge of industrial processes.

Source: cultofmac